The rapid development of e-commerce has raised customer expectations and also placed heavier expectations on distribution centers, the top of the supply chain. For many companies, quickly and accurately transporting or storing mixed pallets containing multiple products has become a top priority, and human resources are often insufficient. One of the latest solutions in the field of automation is the mixed-case palletizing system. Let’s take a look at how this automation technology can unlock higher efficiency for your mixed-case palletizing needs.

1. What is mixed-case palletizing?

A mixed-case palletizing system is a process of stacking various SKUs (Stock Keeping Units) of different sizes, weights, and specifications onto a single pallet to achieve optimal storage or transportation. Unlike traditional palletizing, which stacks uniform products together, mixed-case palletizing involves stacking multiple types of products.

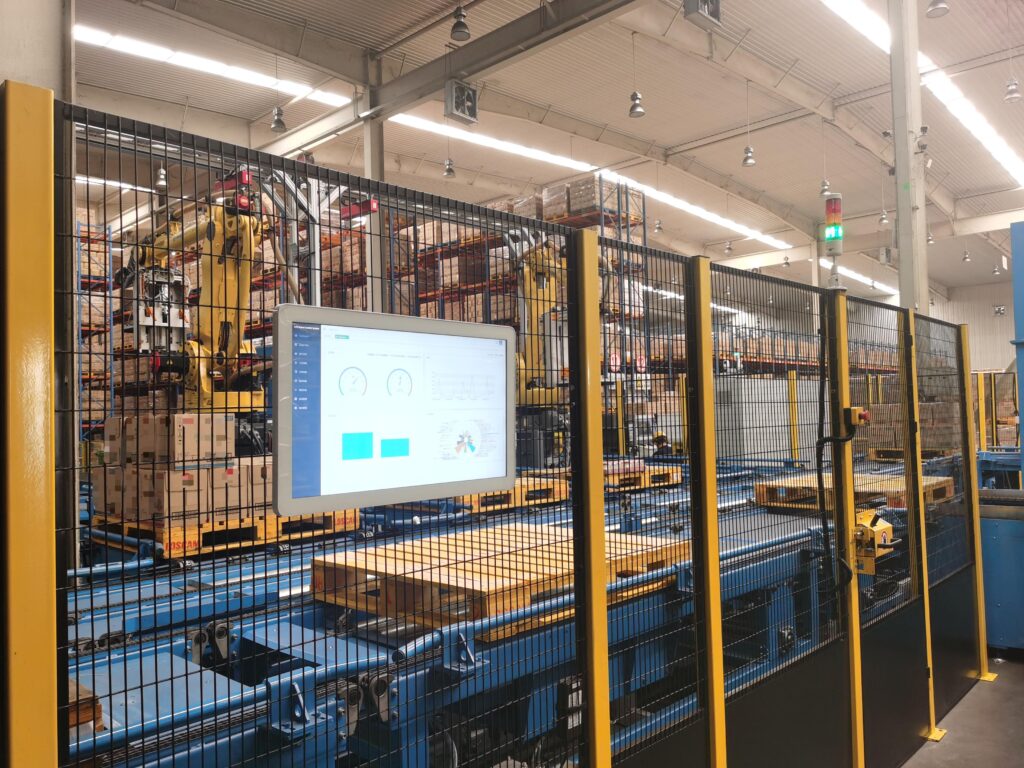

It is an automated device for building mixed-product pallets. Operators can easily input product data through a user-friendly Human-Machine Interface (HMI), and integrated sensors monitor the integrity and stability of the load in real-time.

Many systems integrate automated warehouse robots to perform complex picking and placing tasks. Some systems also use artificial intelligence to connect to the company’s ERP (Enterprise Resource Planning system) to coordinate with inventory and packaging priorities.

2. Which enterprises can benefit from mixed-case palletizing?

Industries that handle products of various sizes and packaging forms are most suitable for adopting mixed-case palletizing. For example, a pharmaceutical company usually not only transports full pallets of a single drug but also needs to transport pallets containing various medicine bottles, large bottles of drugs, or medicine boxes of multiple sizes. What’s more complex is that its inventory may also include more categories such as hair care products, hygiene products, seasonal goods, and even food.

Suitable industry types:

- Food and beverage industry

- Pharmaceutical and daily chemical products industry

- Retail and e-commerce industry

3. Main advantages

1. More accurate pallet stacking

For human workers, handling various SKUs and packaging styles is like playing Tetris, which requires constantly challenging to find the best layout under continuous work demands.

Automated mixed-case palletizing systems enable you to:

① Palletize products using advanced technologies such as robot learning and 3D vision;

② Achieve faster and more accurate order fulfillment;

③ Automate difficult tasks such as picking and palletizing;

④ Avoid unnecessary expenses or costs caused by inaccurate pallet stacking.

① Palletize products using advanced technologies such as robot learning and 3D vision;

② Achieve faster and more accurate order fulfillment;

③ Automate difficult tasks such as picking and palletizing;

④ Avoid unnecessary expenses or costs caused by inaccurate pallet stacking.

2. Higher load density

Automated mixed palletizing solutions can significantly improve load density and stability in the following ways:

- Intelligent algorithms: Generate efficient stacking patterns based on product size, weight distribution, and handling requirements

- Integrated sensors: Monitor the load and use artificial intelligence for real-time adjustments to ensure the safety of the entire process

3. Stronger inventory management

The most effective mixed-case palletizing systems are designed to be compatible with your existing equipment and provide:

- Enhanced visibility: Monitor product flow and performance indicators

- Simplified replenishment process: Can trigger replenishment alerts based on inventory levels

- Comprehensive reporting functions: Enable you to analyze trends, predict demand, and make data-driven decisions

Summary

The mixed-case palletizing system can stack products efficiently and accurately, integrate effectively with your existing equipment, and create compact and stable mixed pallets to optimize transportation and storage efficiency.

You can think of it as the ultimate Tetris champion, easily coping with the palletizing needs of SKUs of various weights and sizes.