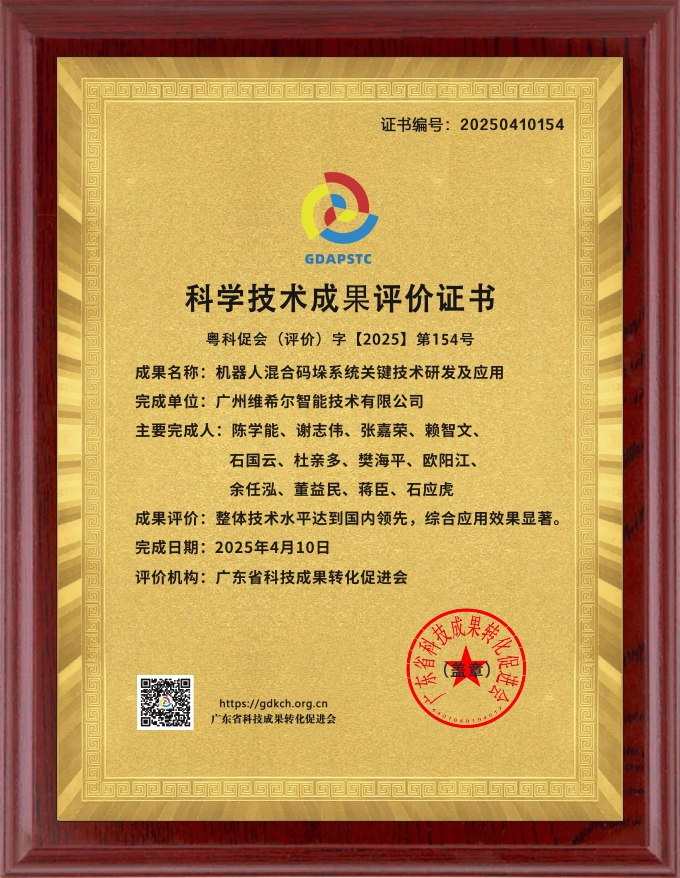

【Exciting News】The key technology research and development and application project of the robot mixed palletizing system independently developed by our company has been recognized as a scientific and technological achievement through authoritative evaluation. This innovative technology not only brings significant economic and social benefits to enterprises but also promotes the transformation, upgrading, and sustainable development of the manufacturing industry.

I. Policy Empowerment + Market Drive: Weixier Responds to Strategic Orientation

As a national high-tech enterprise and a provincial technology-based small and medium-sized enterprise, Weixier deeply responds to the national strategic orientation. Relying on the key deployment of the robot industry in the 14th Five-Year Plan and the goal of “doubling the density of manufacturing robots by 2025” proposed in the “Robot +” Application Action Implementation Plan by the Ministry of Industry and Information Technology, it focuses on the localization of core components and the implementation of intelligent scenarios, and independently develops the robot mixed palletizing system.

As a national high-tech enterprise and a provincial technology-based small and medium-sized enterprise, Weixier deeply responds to the national strategic orientation. Relying on the key deployment of the robot industry in the 14th Five-Year Plan and the goal of “doubling the density of manufacturing robots by 2025” proposed in the “Robot +” Application Action Implementation Plan by the Ministry of Industry and Information Technology, it focuses on the localization of core components and the implementation of intelligent scenarios, and independently develops the robot mixed palletizing system.

In the period of growing market demand, the scale of China’s palletizing robot market reached 31.52 billion yuan in 2024 (a year-on-year increase of 16.8%), and it is expected that the global market scale will exceed 7.6 billion US dollars by 2029 (with a compound annual growth rate of 15.6%). Facing the rising cost of traditional labor and the urgent demand for high-speed and high-precision palletizing in industries such as food, medicine, and new energy, Weixier has successfully applied the research and development of the robot mixed palletizing system through 3D visual fusion technology and mixed palletizing algorithms, achieving a significant leap in production capacity in the short term.

II. Revealing Four Core Technologies: Redefining Logistics Automation Standards

① Intelligent Control System: Dual Engines of Autonomous Navigation and Adaptive Learning

High-precision positioning: Autonomously perceiving the environment for navigation, and accurately palletizing by virtue of high-precision positioning;

Adaptive learning: Applying deep learning and machine vision technologies to continuously learn and optimize to improve efficiency and flexibility, continuously optimize grasping strategies, and automatically adjust working parameters according to production needs to optimize operation processes.

High-precision positioning: Autonomously perceiving the environment for navigation, and accurately palletizing by virtue of high-precision positioning;

Adaptive learning: Applying deep learning and machine vision technologies to continuously learn and optimize to improve efficiency and flexibility, continuously optimize grasping strategies, and automatically adjust working parameters according to production needs to optimize operation processes.

② Visual Information Processing: Industrial Eyes for Millimeter-Level Precision Grasping

Smart pick visual depalletizing technology: Independently developed 3D visual rapid calibration technology, with the re-projection pixel error of the binocular structured light camera scene understanding and rapid calibration module being less than 0.2, and the Z-direction repeatability of the smart camera being 0.5mm-1mm;

Six-dimensional pose estimation: Based on binocular structured light cameras and sorting knowledge bases, the positioning error of six-dimensional pose estimation is less than 1mm, the grasping planning time for a single object is less than 25ms, and the comprehensive grasping success rate for objects with complex textures, high light transmittance, and boxed objects is ≥98%.

Smart pick visual depalletizing technology: Independently developed 3D visual rapid calibration technology, with the re-projection pixel error of the binocular structured light camera scene understanding and rapid calibration module being less than 0.2, and the Z-direction repeatability of the smart camera being 0.5mm-1mm;

Six-dimensional pose estimation: Based on binocular structured light cameras and sorting knowledge bases, the positioning error of six-dimensional pose estimation is less than 1mm, the grasping planning time for a single object is less than 25ms, and the comprehensive grasping success rate for objects with complex textures, high light transmittance, and boxed objects is ≥98%.

③High-Strength Robotic Arm: A Stable Cornerstone in High-Load Scenarios

Adopting high-strength materials, it is stable under high-load and high-frequency operations, with flexible joints that can meet complex palletizing needs. In addition, there are diversified fixture designs, which can design different fixtures for different goods to firmly grasp and position the goods to prevent slipping and damage.

Adopting high-strength materials, it is stable under high-load and high-frequency operations, with flexible joints that can meet complex palletizing needs. In addition, there are diversified fixture designs, which can design different fixtures for different goods to firmly grasp and position the goods to prevent slipping and damage.

④ Motion Control Technology: Double Guarantee of Precision and Safety

PID control + motion planning algorithm: Combined with collision detection sensors to monitor distances in real-time, with a positioning error of less than 1mm. When encountering obstacles, it will alarm or stop moving to prevent collisions;

PID control + motion planning algorithm: Combined with collision detection sensors to monitor distances in real-time, with a positioning error of less than 1mm. When encountering obstacles, it will alarm or stop moving to prevent collisions;

III. Technological Creativity: Building Dual Core Capabilities of “Adaptive Grasping + Dynamic Path Optimization”

Millimeter-level precision control: The visual recognition time of a single object is less than 50ms, the positioning error is less than 1mm, and the positioning attitude error of a single axis is less than 0.5mm;

Extreme learning ability: The positioning learning efficiency for unknown objects is less than 25ms, supporting multiple sets of palletizing schemes to calmly cope with complex scenarios;

International certification: The system has obtained international certification, helping to upgrade green logistics and intelligent manufacturing, and promoting domestic substitution and international cooperation.

Millimeter-level precision control: The visual recognition time of a single object is less than 50ms, the positioning error is less than 1mm, and the positioning attitude error of a single axis is less than 0.5mm;

Extreme learning ability: The positioning learning efficiency for unknown objects is less than 25ms, supporting multiple sets of palletizing schemes to calmly cope with complex scenarios;

International certification: The system has obtained international certification, helping to upgrade green logistics and intelligent manufacturing, and promoting domestic substitution and international cooperation.

IV. Future Strategy: From Technological Breakthrough to Intelligent Manufacturing Empowerment

Weixier will focus on an open strategy, deepen the integration of AI, digital twins, the Internet of Things with logistics scenarios, explore cutting-edge applications such as multi-machine collaboration and cross-scenario scheduling, and jointly promote the innovation and development of robot mixed palletizing systems, contributing to building an intelligent manufacturing system and achieving the goal of a strong manufacturing country.

Weixier will focus on an open strategy, deepen the integration of AI, digital twins, the Internet of Things with logistics scenarios, explore cutting-edge applications such as multi-machine collaboration and cross-scenario scheduling, and jointly promote the innovation and development of robot mixed palletizing systems, contributing to building an intelligent manufacturing system and achieving the goal of a strong manufacturing country.