Solutions > Intelligent Stereoscopic Warehouse Storage System

Intelligent Stereoscopic Warehouse Storage System

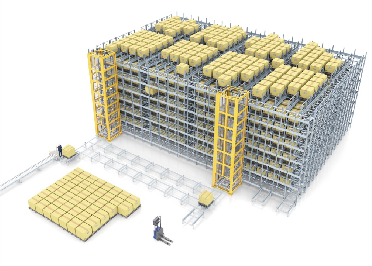

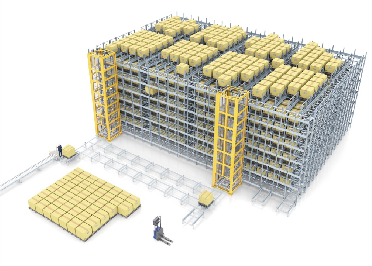

System Introduction: The innovative combination of the four-way shuttle vehicle and the vertical two-way vehicle enables six-way shuttle movement in space. It can be flexibly deployed at any position in front of and inside the warehouse, with a uniform efficiency configuration. It features quick delivery and easy maintenance, and is suitable for industries mainly focusing on storage scenarios such as food, manufacturing, cold chain, energy, chemical industry, and building materials.

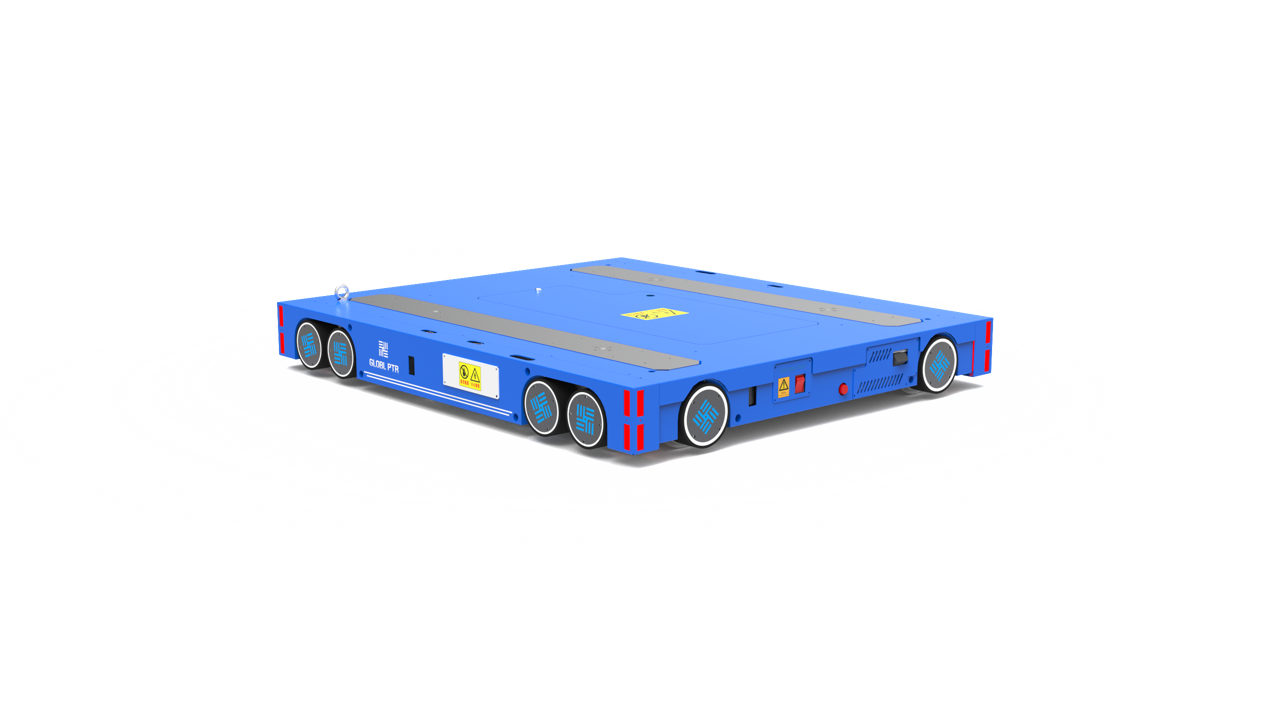

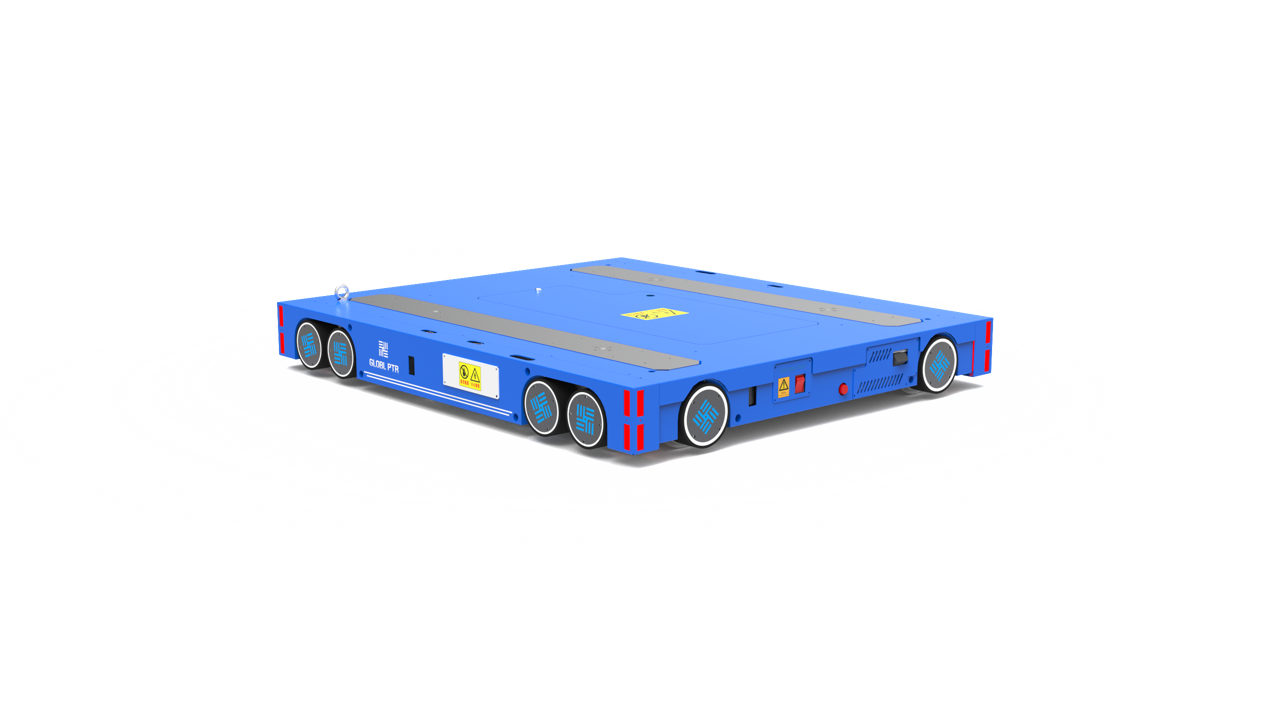

Solution Composition: Four-way shuttle vehicle, pallet elevator, and racking pallets.

[Functional Features]:

1. High Efficiency: The comprehensive efficiency is 2 to 3 times higher than that of traditional warehouses, and 15% to 20% higher than that of ordinary automated stereoscopic warehouses (Stacker Cranes AS/RS).

2. High Density: Replacing traditional elevators and conveyor lines, the vertical two-way vehicle only occupies one storage position, reducing the occupied storage positions by more than 80% compared with the elevator. More storage positions can be planned in the front area of the warehouse, resulting in a higher space utilization rate.

3. High Flexibility: It is suitable for both newly built and renovated warehousing scenarios. Storage positions can be flexibly planned according to the site; the depth of storage positions can be flexibly planned according to SKUs; and buffer positions can be flexibly planned according to the required efficiency.

4. Quick Delivery: It is a standardized product without electrical debugging. It can be delivered immediately after installation, shortening the delivery cycle by more than 80% and significantly reducing the delivery cost.

[Applicable Scenarios]: Food, beverages, agricultural and sideline products, daily necessities, etc.

Solution Composition: Four-way shuttle vehicle, pallet elevator, and racking pallets.

[Functional Features]:

1. High Efficiency: The comprehensive efficiency is 2 to 3 times higher than that of traditional warehouses, and 15% to 20% higher than that of ordinary automated stereoscopic warehouses (Stacker Cranes AS/RS).

2. High Density: Replacing traditional elevators and conveyor lines, the vertical two-way vehicle only occupies one storage position, reducing the occupied storage positions by more than 80% compared with the elevator. More storage positions can be planned in the front area of the warehouse, resulting in a higher space utilization rate.

3. High Flexibility: It is suitable for both newly built and renovated warehousing scenarios. Storage positions can be flexibly planned according to the site; the depth of storage positions can be flexibly planned according to SKUs; and buffer positions can be flexibly planned according to the required efficiency.

4. Quick Delivery: It is a standardized product without electrical debugging. It can be delivered immediately after installation, shortening the delivery cycle by more than 80% and significantly reducing the delivery cost.

[Applicable Scenarios]: Food, beverages, agricultural and sideline products, daily necessities, etc.

Get more productions information

Please contact us:400-025-8418Do you need logistics technology solutions?

WeChat QR code

Tell us about your project, and we will reply with solution recommendations