Solutions > Automated Storage Solution

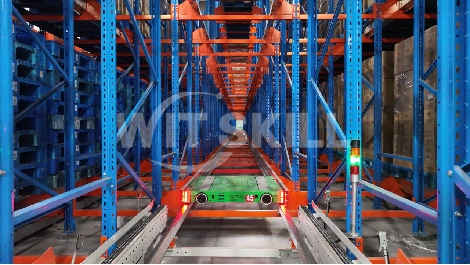

Intelligent Stereoscopic Warehouse Storage System

High space utilization rate

Improve Operational efficiency

Low labor costs,excellent benefit

Value of the Solution |

|

Applicable Industries |

Get more productions information

Please contact us:400-025-8418Do you need logistics technology solutions?

WeChat QR code

Tell us about your project, and we will reply with solution recommendations